Safeguarding Electrical Distribution Boxes: The Critical Choice of Premium Busbars to Prevent Short Circuits

Electrical distribution boxes are integral components of modern power systems. However, short circuit issues can pose serious threats to their normal operation. This article delves into the primary reasons behind short circuits, with a specific focus on overload issues. It advocates for preventing potential risks by choosing high-quality busbars.

Hazards of Electrical Distribution Box Short Circuits

Electrical distribution box short circuits not only lead to equipment damage and production interruptions but also introduce potential safety hazards. Understanding the causes of short circuits is crucial for ensuring the reliability and safety of power systems.

Causes of Short Circuits

Cable Aging and Wear: Prolonged use and external environmental factors can contribute to cable aging, increasing the risk of short circuits.

Equipment Faults: Internal faults in electrical equipment, such as damaged switch components or electrical component failures, are common causes of short circuits.

Poor Insulation: Wear, pollution, or damage to insulation materials can reduce insulation effectiveness, leading to potential short circuits.

Overload Issues: Overloading is a fundamental cause of short circuits. When current exceeds the designed load capacity of equipment, the system becomes unstable, elevating the risk of short circuits.

In-Depth Analysis of Overload Issues

Overloading is a primary driver of short circuits. It not only results in premature equipment failure but also places the system at high risk. Understanding the definition, impact, and distinguishing between transient and sustained overloads is the first step in preventing short circuits.

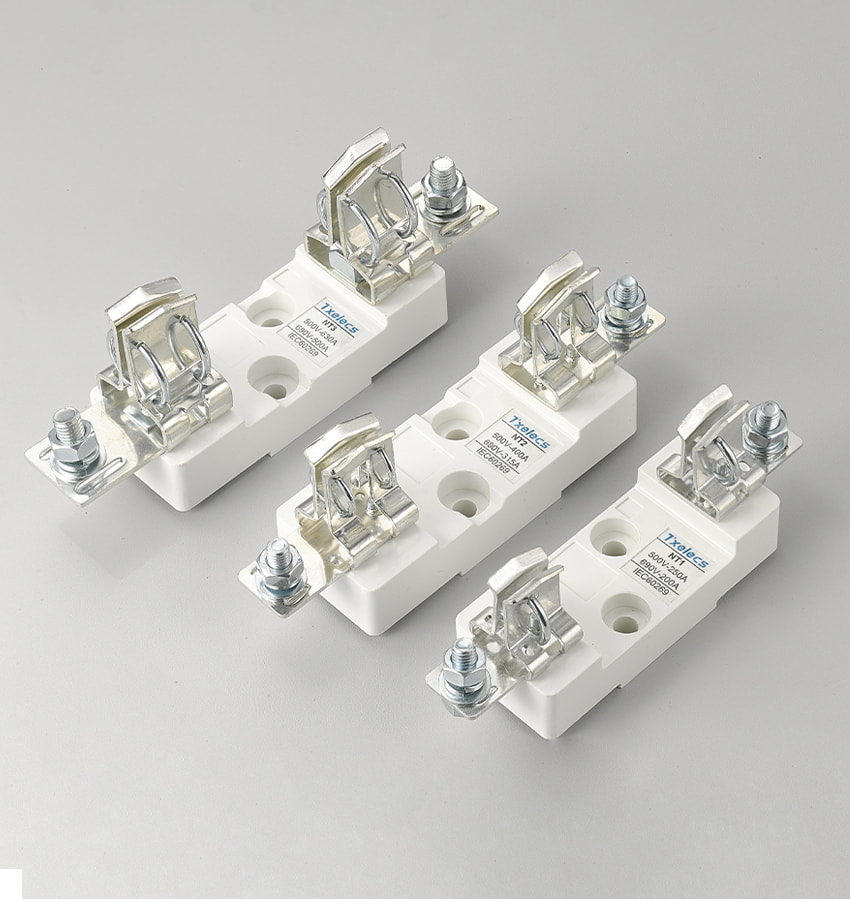

In electrical systems, busbars play a crucial role in current distribution, directly affecting the stability and safety of the system. The choice of high-quality busbars is an effective measure in preventing short circuit issues.

Advantages of Choosing High-Quality Busbars

Enhanced System Reliability: High-quality busbars effectively distribute current, reducing the risk of overloads and enhancing system reliability.

Reduced Short Circuit Risk: Well-designed busbar systems can better handle uneven current distribution and overload situations, thereby lowering the probability of short circuits.

Stable Current Distribution: High-quality busbars ensure a uniform current distribution within the system, minimizing the likelihood of overloads and maintaining system stability.

How to Choose Suitable Busbars

To ensure the normal operation of electrical systems, we recommend:

Consider Current Capacity and Design Standards: Choose busbars with appropriate current capacity based on the actual load requirements of the system and in accordance with relevant design standards.

Understand Manufacturing Materials and Quality Standards: Select busbars manufactured from high-quality, durable materials to ensure optimal performance in various environmental conditions.

Collaborate with Professional Engineers: When selecting and designing busbar systems, collaborate with professional electrical engineers to ensure that the busbar system meets the specific requirements of the system.

Conclusion

By thoroughly understanding the causes of electrical distribution box short circuits and preventing overload issues through the selection of high-quality busbars, we can mitigate the risk of system short circuits and ensure the safe operation of electrical systems. In electrical engineering, investing in premium busbars is a key step in ensuring system reliability.